اترك رسالة

Coal crushing and screening plant NM Heilig

Contact + 31 (0)72 571 66 88 Location: France Industry: Coal grading Capacity: 300 t/h for 025 mm and 825 mm fraction, 180 t/h for 615 mm fraction Scope: 1 Hopper feeder 16 belt conveyors 2 vibrating screens

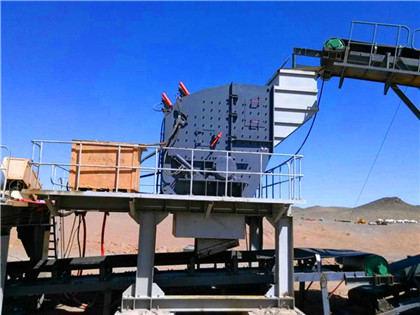

Crushing & Screening Plants MEKA

MEKA designs and manufactures a diverse product portfolio of crushing and screening plants for increased and flexibility on site Our crushing and screening units are flexible, durable and give high classleading

Crushing and Screening Handbook AusIMM

TABLE OF CONTENTS Chapter Subject / section name Preface Table of Contents TON’s Mining and Construction Technology 1 Quarry Process + Process Integration and

Opencast Mine Coal Crushing and Screening Plant YouTube

https://cementcrusher China largest Coal Mine Crushing Plant, 3000t/h processing capacity, located in Xinjiang, China

Crushing & Screening Plant 911 Metallurgist

Methods used in Crushing & Screening Plants on ore range from a simple combination of a grizzly and one crusher to an elaborate arrangement in series of

Coal preparation plant

A coal preparation plant ( CPP; also known as a coal handling and preparation plant ( CHPP ), coal handling plant, prep plant, tipple or wash plant) is a facility that washes

Mining crushing stations TON

Mining Crushing Stations Legacy and expertise TON has extensive experience in crushing and screening plants in the mining industry In fact, we have delivered over 100 complete crushing and screening plants to

MECHANIZED CRUSHING & SCREENING PLANT SpringerLink

This article presents a method and a mechanized crushing and screening plant designed to sort loading of raw coal into gondola cars, in which the

Operation and Maintenance of Coal Conveying System Screening

Coal conveying system usually set a screening crushing machine room; broken coal and screening equipment are used together, complete coal of broken and

Crushing and Screening Handbook AusIMM

TABLE OF CONTENTS Chapter Subject / section name Preface Table of Contents TON’s Mining and Construction Technology 1 Quarry Process + Process Integration and Optimization (PIO) 2 Feeders 3 Crushing Equipment 3 CSeries Jaw Crushers 3 Superior MKII Primary Gyratory Crushers 3 GP Series Cone Crushers 3 MP Series Cone

Coal Screening Roller Screens Coal Handling Plant

Roller Screens are suitable for separating fine, coarse and sticky coal They are used in coal handling plant for preliminary screening and relief to crusher as well to ensure a clog free flow of coal Roller Screens

Coal crushing plant, Coal Crusher, Coal Crusher

EXCT Coal Crushing Plant mainly crushes raw coal mine from opencast working, passes the primary crushing, secondary crushing, even tertiary crushing, then enters into screening system, finally reaches the clients’

Roller Screen Wobbler thyssenkrupp Polysius

For feeding and screening of problematic raw materials The roller screen / wobbler is designed for the classification of coarse, wet, sticky and lumpy material It is mostly applied in case of difficult screening conditions and perfectly suited for transporting the coarse lumps to the crushing installation Our roller screen / wobbler fits to

Coal crusher, Coal crushing plant All industrial manufacturers

jaw crushing plant C6X100 stationary primary coal Capacity: 80 t/h 1,100 t/h Motor power: 110 kW Opening height: 760 mm crushing equipment all over the world since the end of 20 century Nowadays, the C6X Series Jaw Crushers has indisputably become the most popular jaw crusher in the world

Plus 300 TPH Mobile Crusher Plants on Wheels from NAWA

Main Features: Unique combinations to yield up to 350 TPH of 40mm or 250 TPH of 20mm aggregates and crushed sand All three stages of crushing primary, secondary and tertiary on wheelmounted mobile stations PST 1209 (50” x 38”) NAWAJAW crusher on triaxle suspension chassis

(PDF) Crushing and Screening Handbook Academiaedu

These are shown in Figure 2, which shows • Boulder handling two cases: a stationary one and a case where • Crushing & screening the primary section is mobile = inpit crushing, • Material loading which in many cases can yield remarkable ben • Hauling eits because material hauling costs can be re duced considerably

Crushing Plant Design and Layout Considerations 911 Metallurgist

Crushing plant design should accordingly provide for laydown and workspace for onsite equipment refurbishment and repair Where possible, equipment manufacturers should be encouraged to stock and provide spare parts close to the mining operation Good geotechnical information is essential to crushing plant siting and design Installing a

Crushing Plant Flowsheet & DesignLayout 911 Metallurgist

Crushing Plant Flowsheet & DesignLayout In the crushing section, the ore as it comes from the mine is broken down dry to a size suitable for the wet grinding machines ; these can, if necessary, be made to take lumps of 2in size, but they work much more efficiently if their feed is ½ in or less Before the advent of the cs cone

Coal Processing Coal Preparation Coal Handling RPM Solutions

Coal processing involves crushing, screening and beneficiation Processing is where coal is converted from runofmine (ROM) coal to a product that meets the customer’s requirements Mined coal can include lumps Crushing to a manageable size is required Coal crushing can include a two stage process, dependent on deposit size

Complete Crushing And Screening Plants

COMPLETE CRUSHING & SCREENING PLANTS We are one of the Leading Manufacturers of Complete Four stage Crushing, Screening & Washing Plants throughout all over the world with capacity ranging from

MECHANIZED CRUSHING & SCREENING PLANT SpringerLink

This article presents a method and a mechanized crushing and screening plant designed to sort loading of raw coal into gondola cars, in which the ROM is separated by size, thus allowing for a mechanical waling of rock and separate loading of coal, first small and then large grades to prevent floating the coal away from gondola

Crusher, Crushing plant All industrial manufacturers

jaw crusher BR380JG3 mobile Capacity: 50 t/h 240 t/h Motor power: 159 kW Opening height: 1,065 mm Ecofriendly performance moving to a new stage The operating weight of the BR380JG3 ranges from 33,500 to 35,310 kg, with a

Rock Crushers, Stone Crushers, Screening and Crushing

Our TON crushing and screening equipment is engineered for maximum productivity We offer advanced, proven solutions for any sizereduction and classification challenges Fast plant 20 results Stationary cone crushers 800iseries CH895i Cone crusher CH895i Cone crusher Stationary cone crushers 800iseries

Coal Crusher Machine What is Coal Crusher Machine? Fabo

Coal mine is crushed and made ready for use in crushing plants, also known as stone crushing and screening plants And it is brought to small sizes by the crushers in these facilities Generally, three types of crushers are used in crushing and screening plants These are Primary crusher, Secondary crusher and Tertiary crusher

Escalating Demand for Crushing & Screening Plants NBM Media

MB Crusher brings out new Padding Bucket for Loaders & Skid Steers MB Crusher’s new MBHDS220 padding bucket with a 1ton weight and a load capacity of 06 m3 is a versatile and reliable piece of equipment for loaders and skid steer loaders of 45 to 11 tons Compact, versatile and extremely manoeuvrable, the new

The Case for dry processing Multotec

evaluating the available dry processing and dry screening technologies were completed in recent years These studies have provided valuable knowhow and assisted the local coal industry to implement some of these dry processing technologies Some history Dry processing of coal was used quite extensively in the first part of the 20th century –

Lifting and Rigging Incidents Resources Safety & Health

The high potential incidents reported have involved coal mine workers (CMWs) being struck, or nearly struck by loads that were being lifted, lowered, or suspended Incidents reported include: Incident 1 On 16 June 2022, workers were replacing a crushing and screening plant conveyor belt when a rope snapped and struck a